Katni, Madhya Pradesh

- GST NO. : 23AABCT6683L1ZY

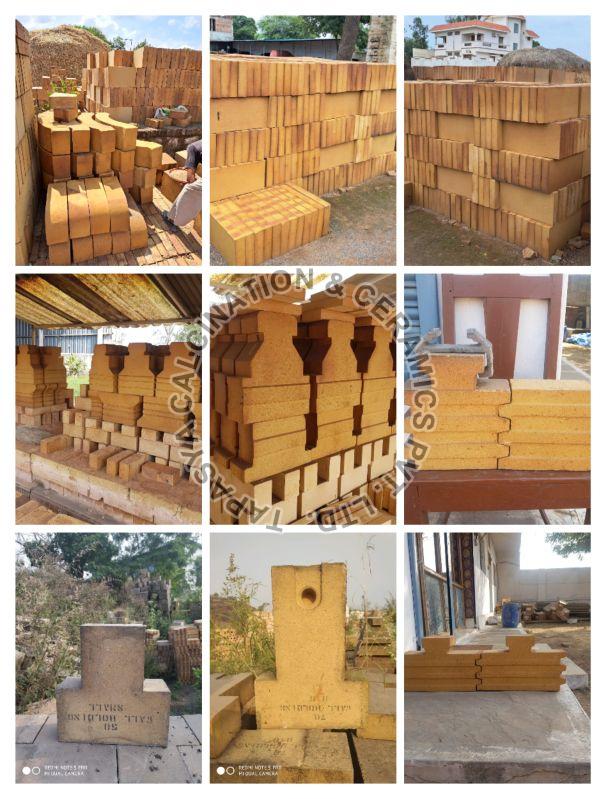

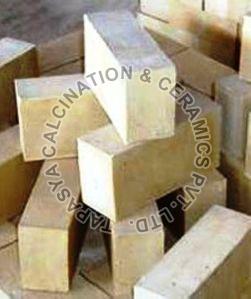

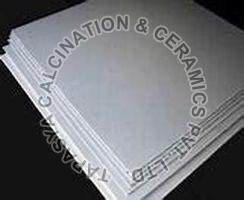

High Alumina Bricks

Price : 125.00 - 3,450.00 / Nos

Get Best Price

| Business Type | Manufacturer, Exporter, Supplier, Importer |

| Material | High Alumina |

| Texture | Solid |

| Shape | Rectangular |

| Click to view more | |

Preferred Buyer From

| Location | All Countries Except India |

Product Details

Color

Brown

Application

Construction

Size

Standard

Country of Origin

India

Industries we serve

- Chemical & Carbon

- Cement & Lime Industries

- Engineering Industries

- Foundries & Metal Works

- Glass & Ceramics Works

- Iron & Steels

- Refineries

- Sugar & Fertilizers

- Thermal Power stations

Technical Details

| Product Name | Chemical Analysis (%) | Apparent Porosity(%) | Bulk Density (g/cc) Min. | CCS (kg/cm²) | PLC(%) | PCE(◦C/0C) Min. | RUL (Ts◦C) | Application Area | |

| Al2O3 | Fe2O3 | ||||||||

| TCC - 30D | 28-31 | 1.7-2.2 | 13-18 | 2.1 | 400-700 | ± 0.5 at 1300◦C/2h | 1330-1360 | Back up of Aluminium pot furnace and other applications. | |

| TCC - 40 | 36-40 | 2.5-3.5 | 17-22 | 2.15 | 350-550 | -0.8 to 0.3 at 1400◦C/2h | 1659/29 | 1350-1400 | Cement preheater,Cyclone, Silicate Furnace & other moderate heat applications. |

| TCC - 40S | 38-41 | 1.8-2.5 | 16-21 | 2.2 | 400-600 | 0.8 to 0.3 at 1450◦C/2h | 1665/30 | 1370-1420 | Special bricks for Cement Preheater & Cyclone. |

| TCC - 42D | 41-43 | 1.3-1.7 | 15-18 | 2.25 | 450-650 | -0.6 to 0.2 at 1450◦C/2h | 1717/32 | 1450-1480 | Dense brick for Blast Furnace & Anode Baking Furnace (ABF) |

| TCC - 45 | 42-45 | 2.5-3.5 | 17-22 | 2.23 | 400-500 | -0.8 to 0.3 at 1400◦C/2h | 1665/30 | 1360-1410 | Cement preheater,Cyclone, Silicate Furnace & other moderate heat applications. |

| TCC - 45S | 42-46 | 1.8-2.5 | 16-21 | 2.25 | 400-600 | -0.8 to 0.3 at 1450◦C/2h | 1683/31 | 1390-1440 | Special purpose Cement Preheater, Cyclone, Chemical Plants,Sulphur Furnaces, Lime Kiln & Glass Tank Furnace. |

| TCC - 45D | 44-48 | 1.2-1.5 | 14-18 | 2.35 | 450-700 | -0.5 to 0.2 at 1450◦C/2h | 1743/33 | 1460-1500 | Blast Furnace, Preheating Zone of Cement Rotary Kiln & Glass Tank Furnace. |

| TCC - RW | 17-21 | 2.25 | 400-600 | -1.0 to 0.2 at 1450◦C/2h | 1683/31 | 1390-1440 | Reheating Furnace Wall | ||

| TCC - 50 | 47-50 | 2.6-3.5 | 17-21 | 2.32 | 450-650 | -0.8 to 0.4 at 1450◦C/2h | 1717/32 | 1400-1450 | Preheating Zone of Cement Rotary Kiln & Reheating Furnace Wall. |

| TCC - 50S | 47-50 | 1.8-2.2 | 16-21 | 2.3 | 450-650 | -1.0 to 0.3 at 1450◦C/2h | 1717/32 | 1400-1450 | Dense brick for Petro-Chemicals,Fertilizer Plants & Anode baking Furnace. |

| TCC - RR | 16-22 | 2.35 | 450-650 | -0.5 to 1.0 at 1450◦C/2h | 1743/33 | 1430-1480 | Reheating Furnace Roof. | ||

| TCC - 55 | 52-55 | 2.9-3.9 | 17-22 | 2.42 | 450-650 | -0.5 to 1.0 at 1450◦C/2h | 1743/33 | 1400-1440 | Preheating Zone of Cement Rotary Kiln & Reheating Furnace Wall. |

| TCC - 55S | 52-56 | 1.7-2.2 | 16-21 | 2.35 | 500-700 | -0.8 to 0.3 at 1500◦C/2h | 1763/34 | 1450-1500 | Reheating Furnace Roof & Petro Chemicals. |

| TCC - SILL | 56-59 | 1.0-1.5 | 17-21 | 2.35 | 400-600 | ± 0.7 at 1500◦C/2h | 1804/36 | 1500-1540 | Glass Tank Furnace & Frit Furnace. |

| TCC - 60 | 57-60 | 3.4-4.2 | 17-22 | 2.5 | 550-800 | -0.4 to 2.0 at 1450◦C/2h | 1785/35 | 1420-1450 | Reheating Furnace Wall, Ladle Back up. |

| TCC - 60L | 57-61 | 2.8-3.8 | 17-22 | 2.45 | 500-800 | -0.2 to 2.2 at 1500◦C/2h | 1785/35 | 1430-1470 | Reheating Furnace Wall, Ladle Back up. |

| TCC - 60S | 58-61 | 1.7-2.2 | 16-21 | 2.45 | 500-800 | -0.4 to 0.8 at 1500◦C/2h | 1804/36 | 1470-1510 | Sulphur Furnace,Alakli Resistant Bricks for Cement Rotary Kin & Ladle Back up. |

| TCC - 60M | 59-61 | 0.9-1.1 | 14-18 | 2.45 | 600-800 | ± 0.5 at 1600◦C/2h | 1820/37 | 1630-1670 | Blast Furnace Stove Checkers,Solid Wall Bricks & Glass Tank Furnace. |

| TCC - 62DB | 61-63 | 1.2-1.7 | 14-18 | 2.45 | 500-800 | ± 0.8 at 1500◦C/2h | 1785/35 | 1500-1530 | Blast Furnace Stove Checkers,Solid Wall Bricks & Glass Tank Furnace. |

| TCC - 62D | 61-64 | 1.2-1.5 | 13-16 | 2.5 | 600-900 | ± 0.5 at 1500◦C/2h | 1804/36 | 1500-1550 | Blast Furnace Hearth,Non-Recovery Coke Oven,Glass Tank Furnace & Frit Furnace. |

| TCC - 628RN | 62-64 | 0.9-1.2 | 42339 | 2.5 | 650-900 | ± 0.2 at 1500◦C/2h | 1820/37 | 1500-1550 at 4kg/cm² | Blast Furnace Hearth,Non-Recovery Coke Oven,Glass Tank Furnace. |

| TCC - 70N | 64-67 | 3.5-4.4 | 17-23 | 2.55 | 500-800 | 0.5 to 2.5 at 1450◦C/2h | 1804/36 | 1440-1470 | Boiler Cupola & Steel Foundry |

| TCC - 70 | 67-70 | 3.4-4.0 | 17-22 | 2.6 | 600-900 | 0.3 to 2.5 at 1450◦C/2h | 1804/36 | 1460-1480 | Boiler Cupola & Steel Foundry & Reheating Furnace. |

| TCC - 70S | 67-70 | 2.8-3.2 | 17-22 | 2.6 | 600-900 | 0.5 to 3.0 at 1500◦C/2h | 1804/36 | 1460-1480 | Burning Zone of Cement Rotary Kiln & Steel Ladle. |

| TCC - 70L | 67-70 | 2.4-2.8 | 16-21 | 2.55 | 600-800 | 0.5 to 2.5 at 1500◦C/2h | 1804/36 | 1460-1480 | Burning Zone of Cement Rotary Kiln & Steel Ladle. |

| TCC - 70/20 | 68-71 | 1.8-2.2 | 16-21 | 2.55 | 600-900 | 0.2 to 2.0 at 1500◦C/2h | 1804/36 | 1470-1500 | Burning Zone of Cement Rotary Kiln & Steel Ladle. |

Looking for "High Alumina Bricks" ?

Nos

Explore More Products